If you like to deal with DIY home projects, you will know that a dedicated workshop may be special in your garage, shed, or basement. It is a small corner of creativity and problems at home where you can make and fix anything else with your hands. It can even be your shelter where you can escape the rest of the house and whatever you have been pressing for a while.

But even a well -designed workshop with a well -designed workshop can turn into a dirt of half -finished projects, mystery patch and tools that seem to be lost, which can end in stress. “A workshop that is organized is more pleasant, more productive and more secure,” says Gary Bexter, who contracts Backter General in Georgia’s Canton. “In place of only a few systems, DIYES can keep your plans on track and use their places throughout the year.”

We talked to many experts about the best tactics to keep the domestic workshop in the tip top form so you can relax and enjoy more space.

Whether your work area is in your garage, shed, or basement, nominate a specific place for each device and put your workshop in order, whether it becomes hook, drawer, or labeled. Caden Wilding, Vice President of Marketing in Wilding Wall Beds in St. George, Utah noted, “A house for everything and everything.” In his workshop, he detects wall tools where he hangs with a sharp to leave a silicing of things going there and then writes his name in Sillet. “So, on the 18 gauge Brad Niler Hook, actually has a sketch on the wall of the device and has a label with the name of the device.”

And the baxter recommends storing small parts together, such as nails, screws, bolts and drill bits. “Store these items with labels in clear poles, jars, or drawers, so that you never waste time digging for the right piece,” says Bexter. “An organized parts system saves frustration and money by stopping the purchase of duplication.”

Organize by work.

Instead of managing the workshop product by type (such as, putting all screwdrivers in one place), try to store them together on a work -based. This can help minimize a smooth workflower, time and energy saving, and clutter. Wilding suggests that “group you use your tools for what projects.” “For example, you will often use Brad Nail with your Chop Ary, so keep them together. It is better, now keep your glue bottle there because you will need it right away.”

Take advantage of the vertical space.

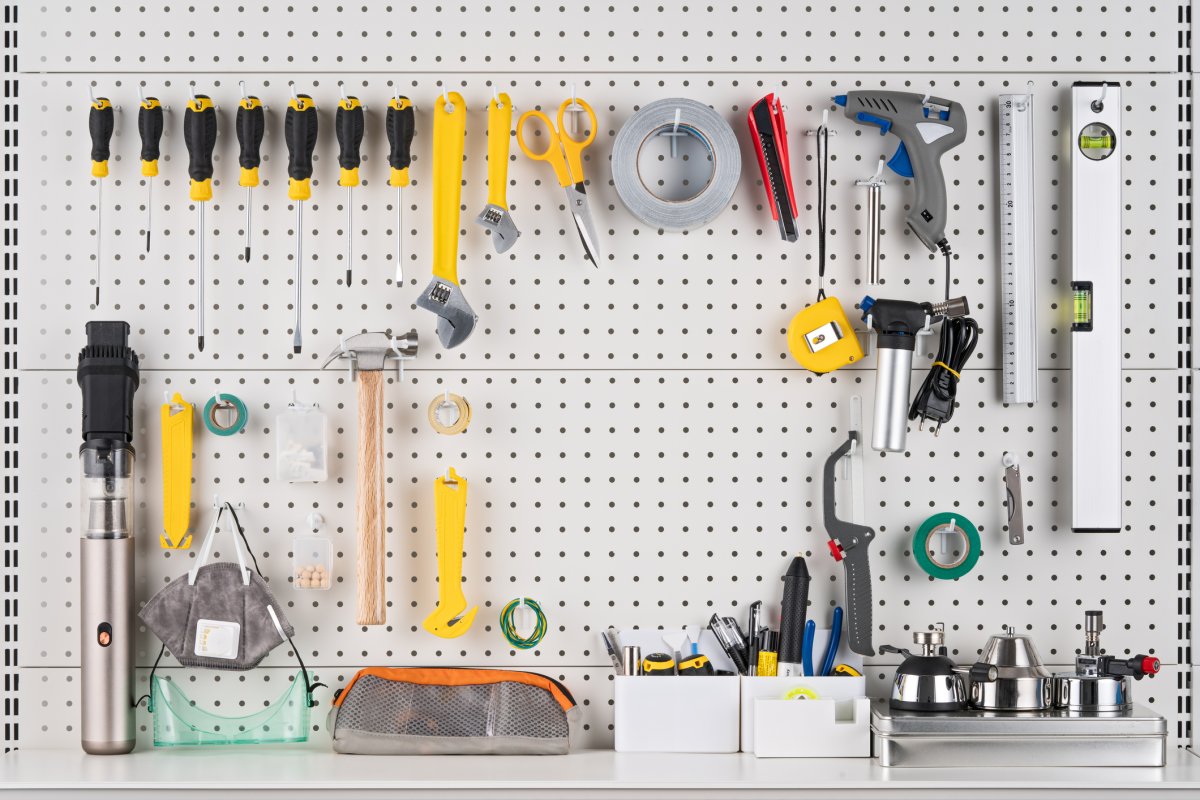

When it comes to organizing your DIY workshop, help free the floor space, the use of a vertical storage solution can be a game changer. Bexter says it also prevents the risks from tripling and speeding up cleaning. Consider applying pig boards from the wall wall to keep the most frequently used tools, visible and easily accessible. It will also help keep your DIY work bench clean up extra.

Nominate zones for different tasks.

Another common indication is to create dedicated areas in the workshop for different materials. “A clean workshop begins with setting,” says Bexter. “Put one area of wood work One area, the other for painting/fining, and the other for common repair. It prevents the tools and equipment from over -liping and makes it easier to find your needs.”

In the California city of Industry, link kitchen COO and co -founder Josh Kian uses an organizational technique that allows it to keep all projects in a designated area, such as containers, trays, or rolling carts. Cain explains, “For a project, all tools, content and hardware can eliminate the dirty and chaos that arises from working on numerous projects simultaneously.” “When I finish the previous project, I put everything in my place before starting the next project.”

“An organized parts system saves frustration and money by stopping the purchase of duplication.”

Gary Bexter, Backster General Contract

Clean and declared daily.

Another helpful way to keep your workshop in the best shape is to clean up as you go. Kian advises, “Instead of waiting until the end of the project for a big cleaning, start making it a habit to clean your dirt when you make them.” When you finish cutting a piece of wood, for example, sweep the knife from the work table and waste the scrap now. “All small efforts will feel less than a big effort to correct the dirt, thus allowing you to work on your plans to maintain permanent flow and speed.”

Invest into an effective space to control the dust in your own workplace to help protect your health and tools. You also want to add a dedicated air filtration system to deal with a better air -driven dust. Ken explains, “Keeping the sticks and other debris regularly clean, especially when working on a project, will prevent the dust from entering your tools.”